Carbide End Mills

-

$1.88

-

$2.45

Reviews & Ratings

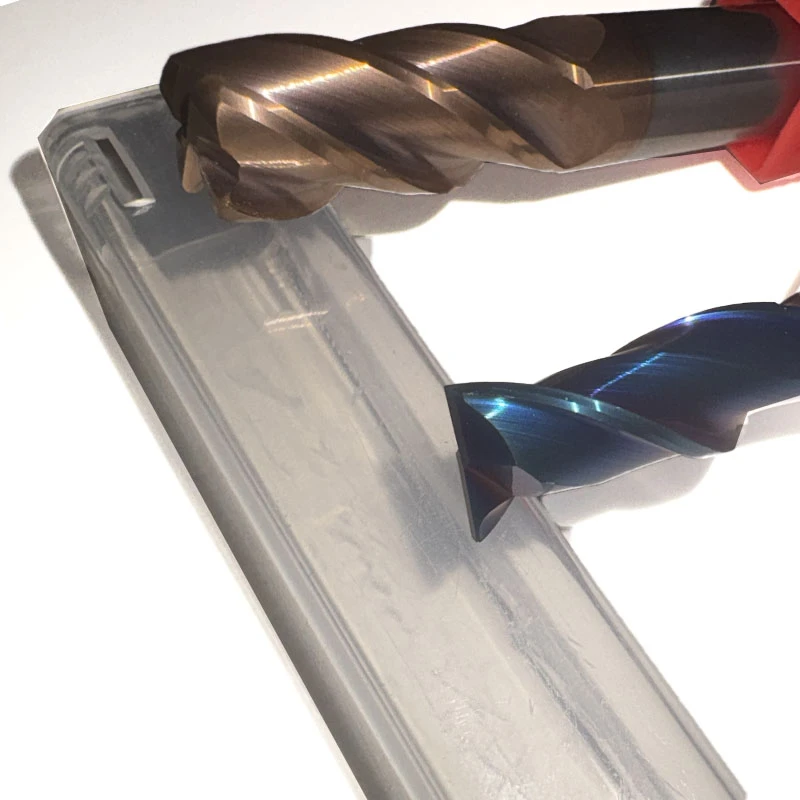

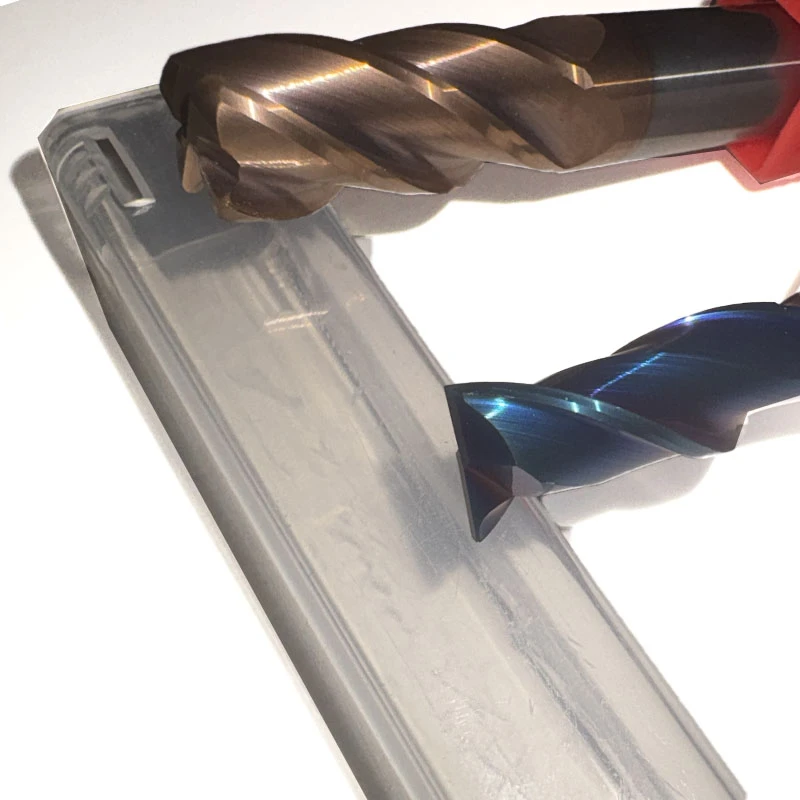

Carbide end mills are amongst the most durable and long-lasting available on the market today. Alongside polycrystalline diamond, tungsten carbide is the toughest material to craft end mills, drills bits, and tool tips. Therefore, Carbide endmills provide a high-performance solution for all manner of tooling jobs, including slotting, finishing, roughing, and profiling.

Product Parameters

| Name | Carbide End Mills/CNC Machine Milling Cutters/CNC Milling Tool |

| Carbide | 100% raw materials |

| HRC | 45/55/60/65 Degree |

| Workpiece Material | Stainless Steel/Cast lron/Aluminum/Copper/Alloy Steel/Harden Steel etc. |

| Flute | 1/2/3/4/6/8 |

| Application | Slotting/Finishing/Roughing/Profiling |

| Our Equipment | Michael Deckel/ANCA/TTB |

| Coating | AITiN, TiAIN, TiSIN, Naco |

| Advantages | High Precision/High Speed Cutting/Good Wear Resistance. |

| Diameter | 1-20mm |

| Total Length | 50-150mm |

| Service | OEM/ODM Available |

| Series | Flat End Mills/Ball Head End Mills/Corner Radius End Mills/Aluminum End Mills/Roughing End Mills/Chamfer Mills/Spot Drills/Spiral Router Bits |

Introduction of the Coating

| HRC | Coating | Color | HV | μm | Friction | The Max °C |

| HRC45 | AITin | black | 3300 | 1-4 | 0.7 | 850°C |

| HRC55 | TiSiN | bronze | 3400 | 1-4 | 0.7 | 900°C |

| HRC60 | AlCrSiN | black | 4000 | 1-7 | 0.35 | 1100°C |

| HRC65 | nACo 3 Blue | blue | 4500 | 1-7 | 0.45 | 1200°C |

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

$1.88

-

$2.45